SURFTRAP

Development and Optimisation of a Process to

Biosynthesize Reactive Iron Mineral SURFaces for Water TReAtment Purposes

Research cooperation project at the special program GEOTECHNOLOGIEN,

main topic: ‘Mineral Surfaces: From Atomic Processes to Geotechnology’

Research code (FKZ): 03G0714 runtime: 2008/07/01 to 2011/06/30

Coordinator: Prof. S. Peiffer, Department of Hydrology, University of Bayreuth

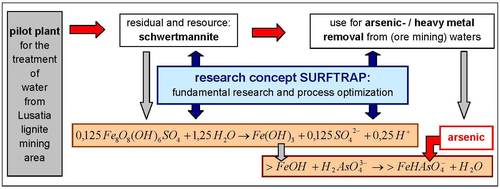

The object of this cooperative research project is the development of a low-cost technology to remove arsenic species from raw waters. The proposed technology is based on the reactivity of schwertmannite, an oxyhydroxo sulfate of the mean stochiometry Fe8O8(OH)6SO4. This mineral typically forms in acidic and sulfate rich mine waters as a secondary mineral upon oxidation of Fe(II) in a biologically mediated process. Schwertmannite can be generated in a biotechnological process after aeration of mining process waters. It rapidly transforms into ferric hydroxides of high specific surface area once exposed to water containing at least some alkalinity. Our rationale follows the concept to make use of this transformation reaction by adding biosynthesized schwertmannite to contaminated raw waters where it generates a large sorption capacity to remove the pollutants. The proposed process to generate reactive surface sites is advantageous both, in economical and ecological regard compared to existing techniques. It requires per mol iron oxide formed only 8 % of the amount of alkalinity compared to the use of Fe(III) containing salts, and releases only 4 % of the amount of salts.

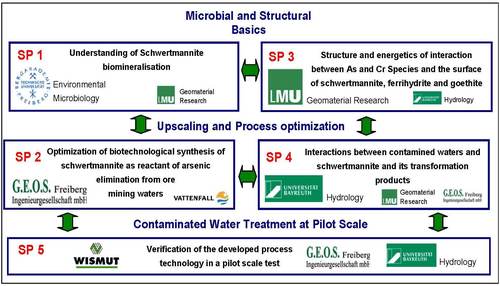

At the research cooperation project, these innovative water treatment concept should be developed from microbial and structural basics, upscaling and process optimisation at laboratory scale to the point of a first, practical application at pilot scale by three academic research groups,

· the department of Environmental Microbiology, Institute for Biosciences, TU Freiberg (TUF, Germany)

· the department of Hydrology, University of Bayreuth (UBT, Germany) and

· the department of Gematerial Research, University of Munich (LMU, Germany)

a medium-sized enterprise:

· G.E.O.S. Freiberg Ingenieurgesellschaft mbH (GEOS, Halsbrücke, Germany)

as well as the collaboration of the industry partners

· Vattenfall Europe Mining AG (Cottbus, Germany) and Wismut GmbH (Chemnitz, Germany).

The scientific objectives of the project were investigated into different subprojects (SP):

· SP 1 (TUF) will concern the optimisation of the schwertmannite synthesis process with special emphasis on the understanding of the role of biomineralization.

· SP 2 (GEOS and Vattenfall Europe Mining AG) will contain the optimisation of the biotechnological process for the schwertmannite generation in an existing pilot plant.

· SP 3 (LMU) will provide a contribution to the understanding of the long-term stability of contaminants bound to the surfaces of precipitated ferric (hydr)oxides with regard to binding stability and redox state in order to evaluate the potential for disposal of the sequestered substances.

· SP 4 (UBT) will provide a contribution to understand kinetic aspects of the interaction between contaminated raw water and the surface of schwertmannite and its transformation products and concerns the optimisation of this process at laboratory scale.

· SP 5 (UBT, GEOS and Wismut GmbH) will contain a pilot scale test of the developed water treatment process in order to compare the novel technique with conventional treatment technologies with regard to efficiency and costs emphasizing on arsenic containing effluents from mine sites.